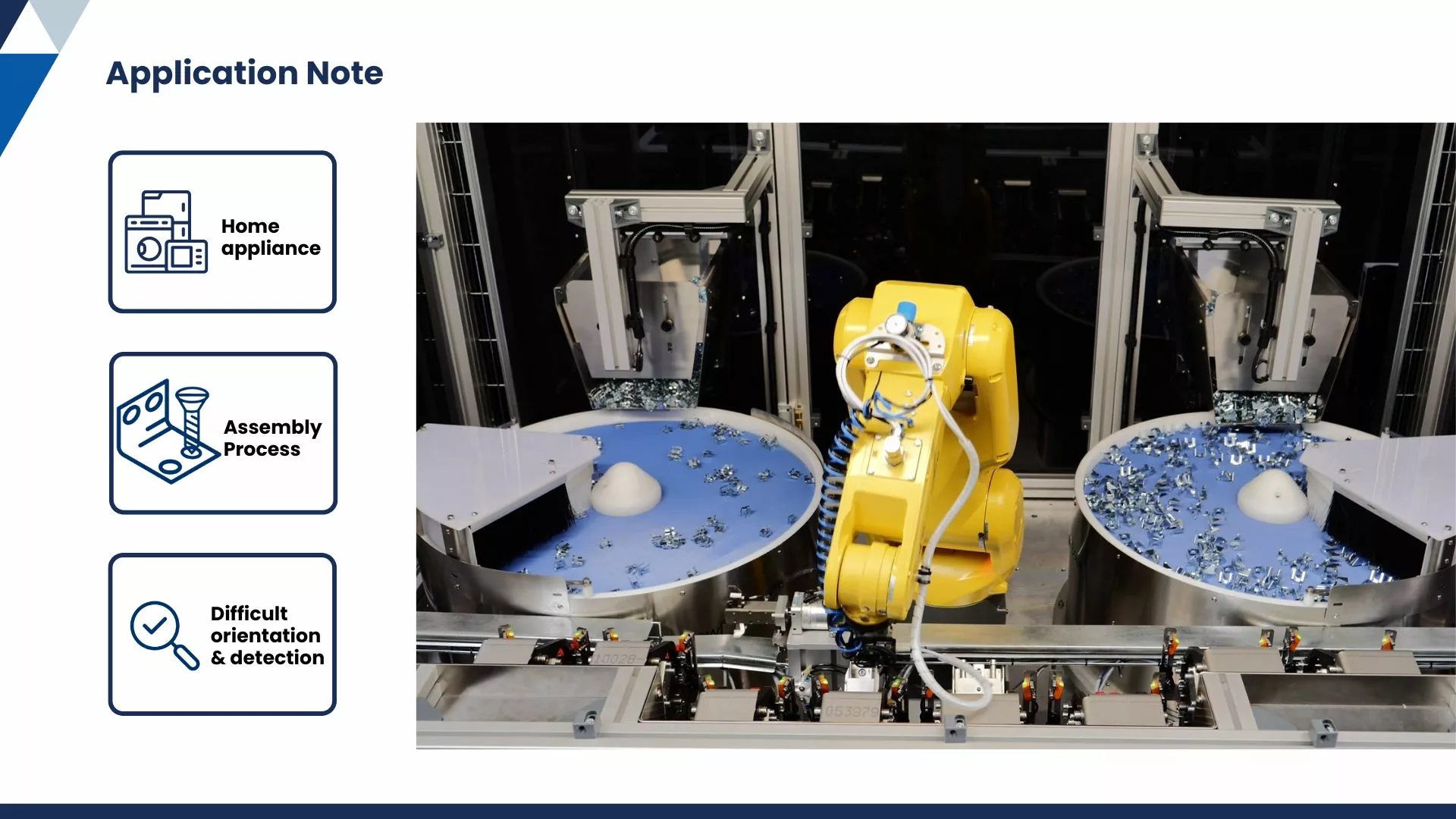

Automated handling of metal clips: flexibility, precision, and compact layout for the home appliance industry.

Case Study: the parts managed by this application are metal latch components for seat belt systems, available in two mirror-image versions.

The Challenge

- Handle reflective metal clips, ensuring effective separation and feeding without overlapping or jamming.

- Ensure high production throughput with continuous and reliable flow, avoiding downtime even with complex or irregular shapes.

- Maintain high quality standards throughout the entire assembly process.

- Optimize production layout with a compact solution that doesn’t compromise performance or productivity.

The Solution

- Two FlexiBowl® 650 units for handling components with complex shapes.

- FANUC LR Mate 200iD robot for fast and precise operations.

- Integrated FlexiVision® system for accurate clip recognition.

- Placement onto linear track to ensure correct alignment in the downstream process.

The Benefit

- Speed: continuous feeding with significant reduction in downtime caused by overlapping clips.

- Quality: optimized production process while maintaining high-quality standards in every cycle.

- Flexibility: efficient handling of complex and irregular parts with minimal manual intervention.

- Optimized layout: maximizes space utilization without compromising performance.