High-speed automatic assembly of latch components for seat belt locking mechanisms

Case Study: the parts managed by this application are metal latch components for seat belt systems, available in two mirror-image versions.

Our partner

From 1975, Samac provides customized equipment for automated assembly and testing processes of mechanical, electromechanical and hydromechanical components. The service starts from the development of the solution to the after-sales, passing through the design, manufacturing and installation.

The Challenge

- Assemble a pin into a metal latch component in two mirror-image versions: right and left.

- Achieve a cycle time of 0.9 seconds per piece, equal to 4,000 pieces/hour.

- Automatically handle two different product types while minimizing downtime and retooling.

- Maintain a compact layout.

The Solution

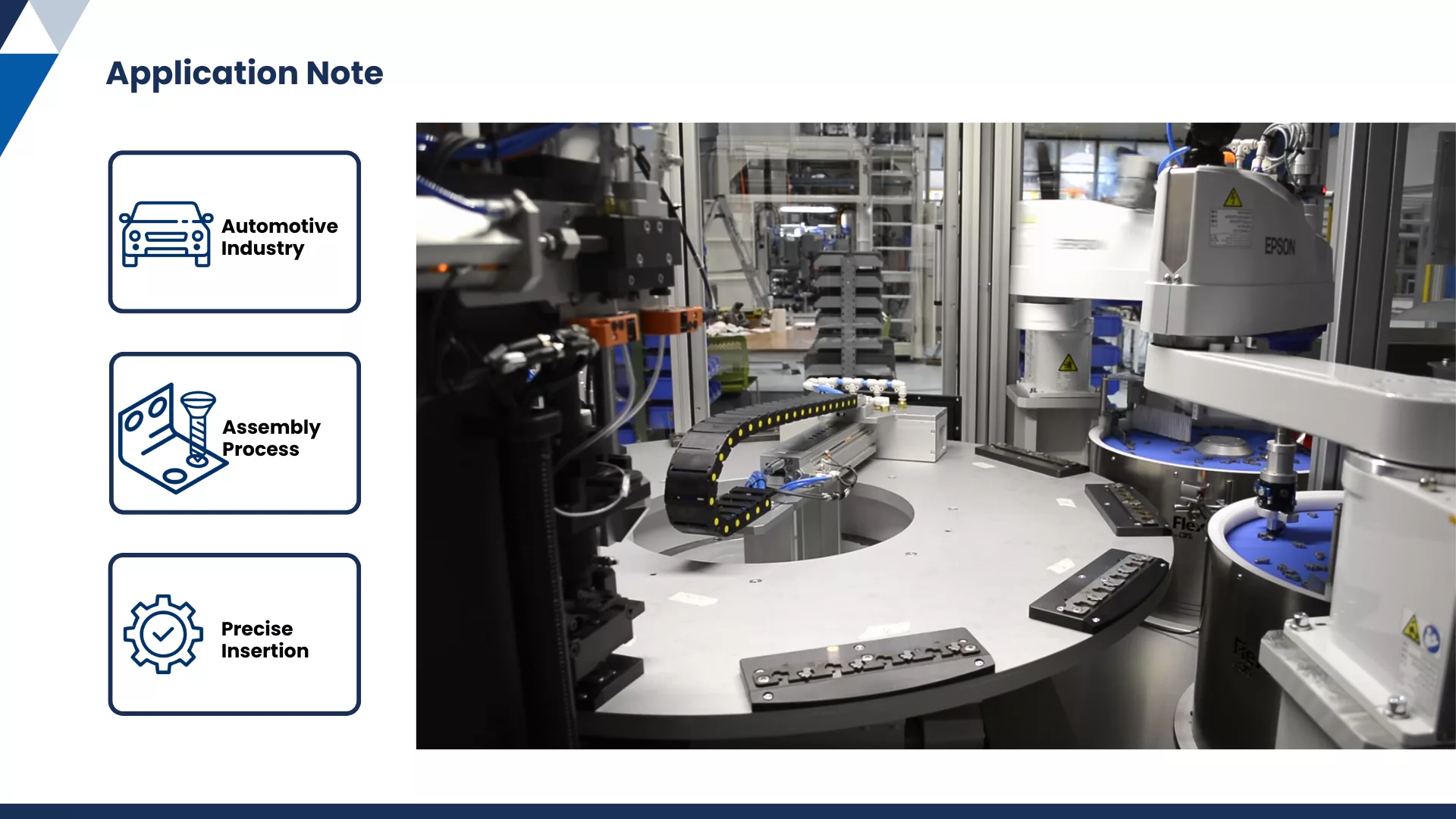

- Two FlexiBowl® 500 units fed by a central hopper for part separation and orientation.

- Vision system with Epson robot for accurate part recognition and pick-up.

- Integrated rotary table for pin insertion and part unloading.

The Benefit

- Speed: competitive cycle time of 0.9 s/piece, equal to 4,000 pieces/hour.

- Precision: accurate pick-up and insertion of latch components thanks to vision system and Epson robot.

- Flexibility: automatic model changeover with no mechanical retooling.

- Compactness: clean layout with dual channel and minimal footprint.

- Reliability: continuous operation without interruptions for cleaning or part selection.