How to Handle Transparent and Complex-Shaped Parts

Case study: a flexible feeding solution for the assembly of transparent medical filters

Our client

The company is a global leader in the production of respiratory diagnostic devices, renowned for technical excellence and continuous innovation.

The Challenge

- Handling transparent and complex components that tend to interlock, making traditional feeding systems inadequate.

- Ensuring precise placement in assembly jigs to maintain product quality and integrity.

- Preventing damage and misalignment when handling plastic parts, in compliance with medical industry standards.

The Solution

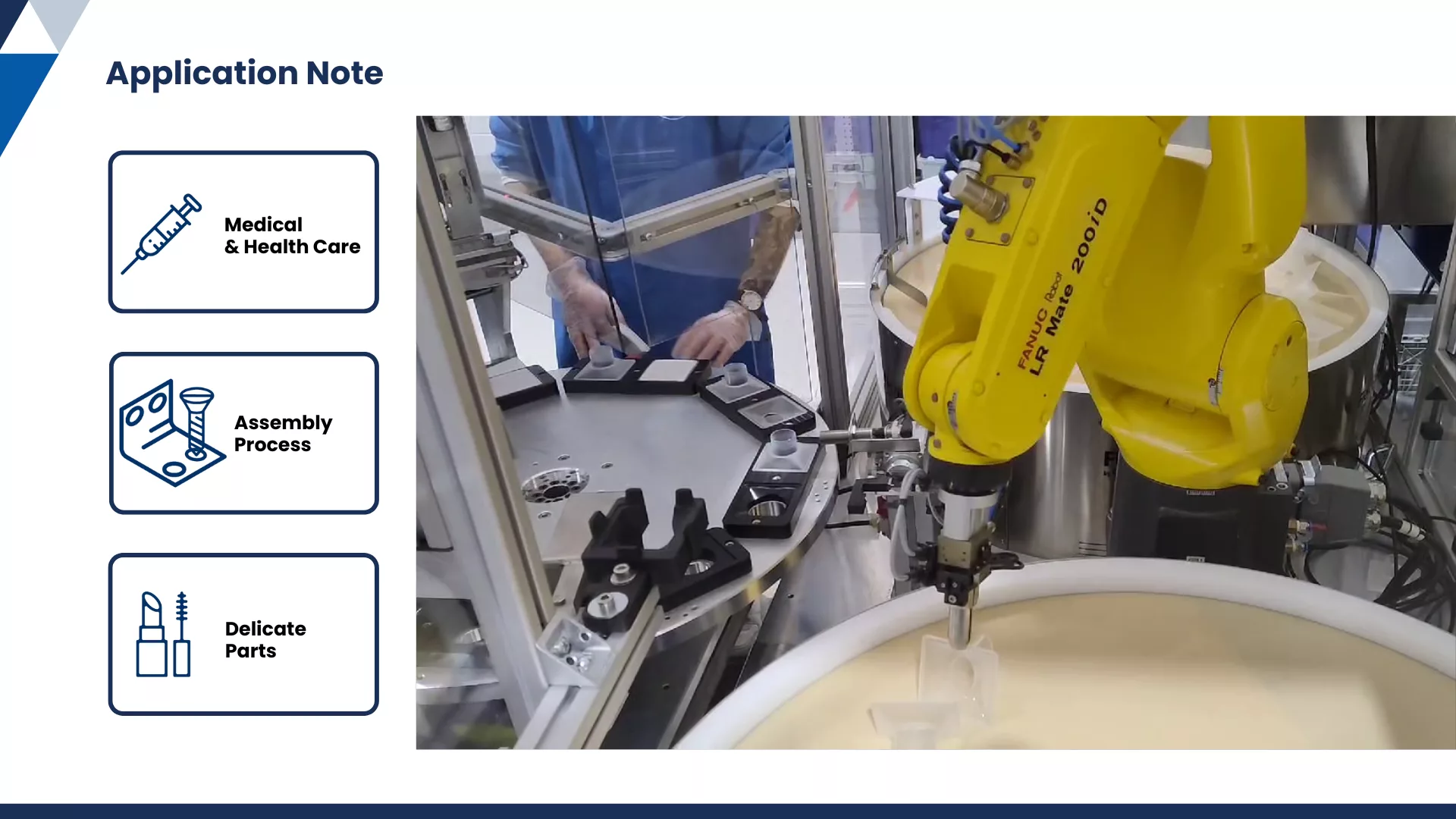

- 2 FlexiBowl® 800: ideal for large, transparent components with irregular geometries, ensuring gentle separation and uniform distribution, preventing jams.

- FANUC LR Mate 200iD Robot: equipped with an EOAT suction system for accurate picking and precise placement of filters.

The Benefit

- Scalable and reliable layout: designed to ensure continuous production and easy maintenance.

- Precision: gentle handling and accurate placement, even with transparent and irregular parts.

- Flexibility: ability to adapt to complex components without structural modifications to the system.

- Efficiency: reduced line downtime and increased productivity in high-criticality medical environments.